Advanced Vehicle Technologies

Our

Services

-

Benchmarking & Advanced Project Planning

Identification of competitive vehicles and chassis technology. Component benchmarking, measurement, testing, Component scanning.

Chassis and vehicle target setting. Key technology identification and research Competitive vehicle K&C data analysis and target setting -

Project Planning

project planning a competitive position and analysis of industry trends

-

ADAMS Analysis & Vehicle Dynamics

Multibody dynamics model creation and analysis in ADAMS or MotionView.Suspension and steering compliant geometry definition and optimization to meet competitive targets:Steering, Ride, Handling, Friction, Braking, Regenerative Braking, Power On/Off Impact Harshness.Load analysis for prototype vehicle component design.Tire envelope definition and generation for packaging. Competitive vehicle analysis and model correlation

-

NVH Analysis & Electric Motor Mount Design

Electric motor mount rates and specifications

Chassis and powertrain NVH analysis -

Brake Systems Analysis & Design

Brake system analysis and specifications

Brake rotor and caliper sizing analysis and specifications. Brake booster requirements

Brake pedal actuation design. Electric parking brake design and actuation. Brake system analysis to meet FMVSS requirements.Wheel bearing design to meet durability requirements.Suspension geometry design to meet failed brake booster test (FMVSS 135).Brake system development:ABS,Traction, control,Yaw stability control. Regenerative braking. Electric parking brake -

Vehicle Package Integration

Chassis architecture feasibility studies during the advanced engineering phase.Chassis architecture definition to meet competitive targets and vehicle specifications.Iteration with Catia/ADAMS to package competitive geometry, chassis technology features, and component design.Suspension, steering, subframe design by AVT. Single or multi-chamber air suspension

CDC Dampers.Four wheel steering – single or dual actuators.Active roll control. Electric vehicle battery under floor or in tunnel. Multiple electric motor configurations – front, rear, single, dual, offset, or concentric. Fully electric, ICE, or hybrid vehicle powertrains.Kinematic DMU creation in Catia.Supplier component integration – in the absence of supplier data AVT will create surrogate CAD from benchmark data.Component specifications for suppliers.2D Component drawings with GD&T manufacturing tolerances -

Wheels and Tires

Tire performance specifications. Tire profile creation. Tire envelope creations. ETRTO and T&RA specs.

-

Prototype Vehicle Design & Build

Component to full vehicle prototyping

Prototype vehicle design

Prototype vehicle component fabrication

Prototype vehicle build

Road load data acquisition

Design validation

Show cars

AVT Offers:

Full service chassis engineering solutions – benchmarking, design, analysis, prototype vehicle design and build, trouble-shooting/resolution, consulting. Expertise in suspension, steering, four wheel steering, brakes, wheels, tires, chassis components, chassis/powertrain NVH; ICE, hybrid, and electric vehicle chassis design expertise.

•Full Chassis Benchmarking

•Innovative Architecture Designs

•Complete Component Design and Release

•Component to Full Vehicle Prototyping

•Mule Car Builds

•Road Load Data Acquisition

•Concept to Production Program Management

Our

Team

-

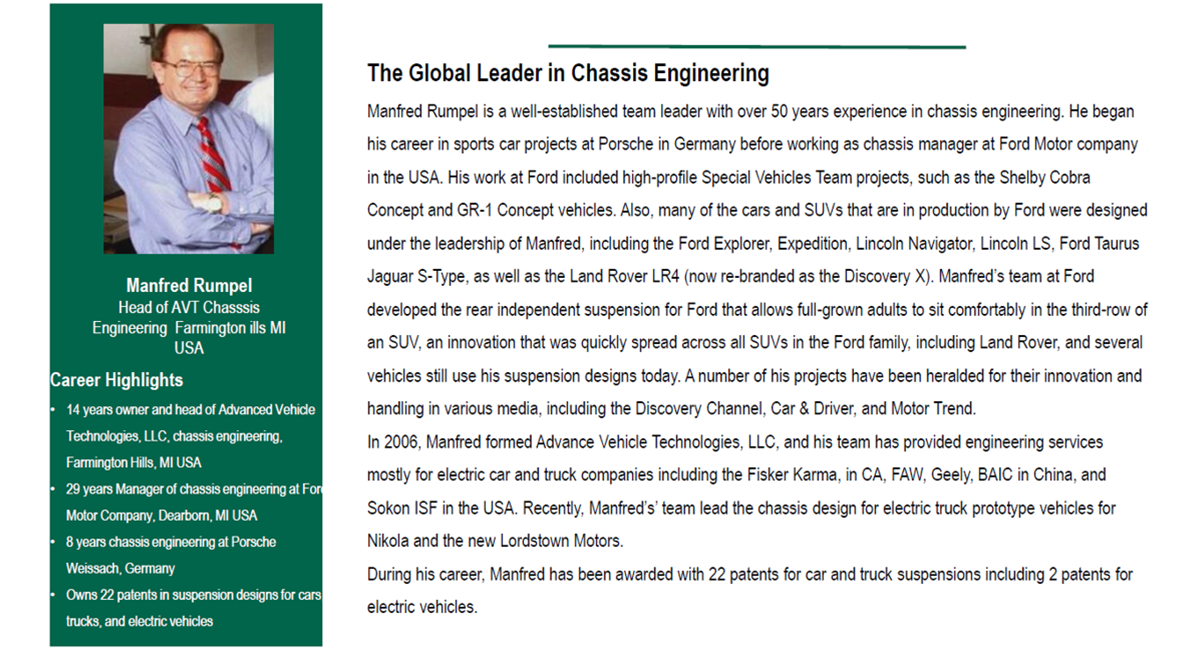

President

40+ years experience in chassis design and development former manager of Advanced Chassis at Ford, 8 years at Porsche working on race cars, production cars, armored vehicles; Awarded 22 patents in field of chassis, electric car suspension, four wheel steering, air suspension, etc. includes Ford Chassis, Thunderbird, Explorer, Expedition, Taurus, Lincoln LS, Jaguar S, Porsche 924/928, as well as numerous international vehicle programs in Japan, China, and Europe.

-

Senior Design Engineer

30+ years experience in chassis design; AM General heavy truck, Ford production cars/suv’s/trucks, Ford Advanced Chassis Group. Owns five patents for suspension design

-

Design Engineer

25+years chassis component design at ZF, steering columns at Admiral Tool, chassis design at Visteon; Design of ball joints, control arms, chassis components; Design for mass production feasibility.

-

Design Engineer

30+ year experience Ford Motor Company. Chassis design, body structure design, surfacing design, prototype vehicle build.

-

Senior Technical Specialist

10+ years chassis engineering experience, multibody dynamics analysis, suspension compliant geometry definition, four wheel steering, flexible bodies, chassis benchmarking and target setting, competitive K&C test data analysis, road load analysis.

-

NVH Specialist

25+ years experience in P/T NVH analysis and development, extensive experience in electric motor mounting; Chassis NVH expert; Former technical specialist in Ford; International experience including Europe, China, India, Australia, and Japan.

-

Brake Expert

30+ years experience in foundation brake design, analysis, and development at Chrysler; Brake system sizing and specifications for meeting FMVSS and ECE regulations; Brake testing and development.

-

Wheel & Tire Expert

30+ experience Ford Motor Company. Technical specialist. Tires, wheels, fasteners.

-

Design & Release Engineer

28+ years experience chassis engineering at General Motors. 4 years ZF Industries Northville Michigan. Chassis component design, analysis, engineering specifications.

-

Benchmarking Technician

5+ years experience Chassis benchmarking, component scan data creation, vehicle functional targets.BOM.